3D Printed Keyguards

Posted by Keyguard AT Design Team on 1st Feb 2024

Originally published Feb. 9, 2021

Keyguard AT now provides 3D printed keyguards as an option. Why would you want that? Our standard acrylic-styrene keyguards are laser-cut, which means that all the openings are cut at a 90° angle to the surface. While the laser "polishes" the edge of the opening, the angle can still feel sharp. Still, laser-cutting keyguards allows for the most precision of any manufacturing method, with the most flexibility of design.

Our CNC-cut polycarbonate keyguard edges are beveled at a 45° angle, removing the sharpness of the edge, but because they are cut on a router, the edges aren't polished like a laser-cut keyguard. Polycarbonate keyguards are the strongest keyguards, with a lifetime warranty against breakage.

However, 3D printing allows us to round the edges of the openings, giving them the "softest" feel of all.

Keyguard AT printed keyguards are available in 3 thicknesses: 2 mm, 3 mm, and 6 mm. We can actually make them any thickness upon request. With sheet-cut keyguards we are limited to the thickness of the available sheet stock.

Resin Printed Keyguards

Keyguard AT is now manufacturing keyguards 3D printed with a polyurethane acrylate resin. A liquid polymer is cured with ultraviolet light into the final shape.

Resin printing allows us to develop new attachment methods and add tactile markings in the future, but the greatest benefit right now is that we can round the edges of the openings, resulting in a keyguard which is much softer to the touch. The polyurethane resin is very strong with a smooth finish and is available in gray or black.

The image on the right shows a keyguard printed with polyurethane resin. Notice the nicely rounded edges on all the openings.

Why not 3D print? Well, 3D printing is improving all the time, and will no doubt get better in the future, and it will allow us to do remarkable things that we can't do now, but for now, it's a pretty immature process. The surface texture is rougher compared to laser-cut or CNC-routed keyguards, with tiny striations left by the printing process giving it an unfinished look. The surface texture also makes a keyguard harder to clean, and leaves little places where bacteria can hide.

3D printed keyguards at present do not have the clarity of cut keyguards. We're working on printing with clear materials, but are not yet satisfied with the clarity we can get. When we are, we'll offer them.

Filament-Printed Keyguards

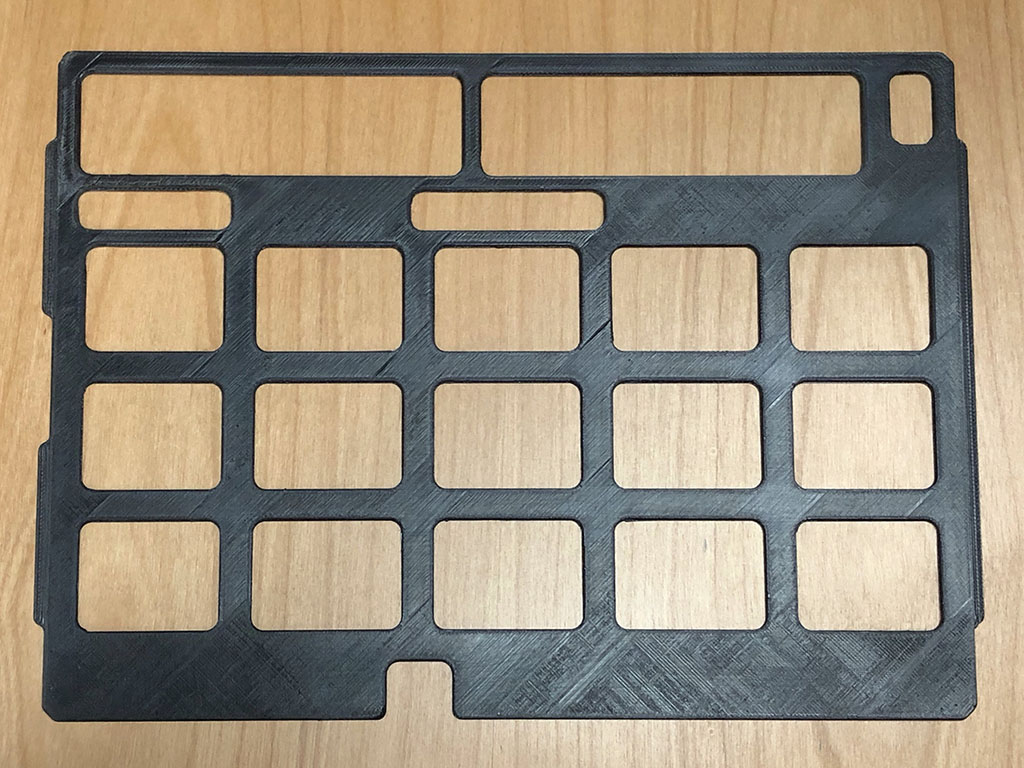

Keyguard AT no longer makes filament-printed keyguards, but we left this section in for comparison.

Filament printing, technically called Fused Deposition Modeling (FDM) is an alternate form of 3D printing where heated plastic is deposited on a platform in layers to create the final shape. Compared to resin printing, FDM printing prints at a much lower resolution, leaving a much more textured surface. Rather than truly rounded edges, the openings have more of a slightly stepped edge. However, FDM printing can be a good choice for users with sensitivity to photopolymers. (Actually, some students with tactile issues may prefer the coarse texture to a smooth keyguard.)

The image on the right shows a filament-printed polycarbonate. Note the textured surface.

FDM printed keyguards are weaker than cut keyguards due to the air that is incorporated in the material between the printed layers. Keyguards printed with PLA, the most common material, are easily broken. We'll make you a PLA keyguard upon request, but we won't guarantee it against breakage. Instead, we print with polycarbonate, the same material used in our unbreakable CNC-routed keyguards. Printed polycarbonate is nowhere near as strong as cut polycarbonate, but it results in the strongest 3D printed keyguards we can make. While long life may not be an issue for users who will graduate to a higher-level keyguard soon, long life is still a consideration for many users, especially those with behavioral issues.

Conclusion

If you're concerned about the 90° angles on a conventional laser- or CNC-cut keyguard, and are OK with the lack of transparency, you might like to try a printed keyguard. If you need a clear keyguard, or don't like the unfinished look of printed keyguards, you should stick with our laser-cut or CNC-routed keyguards.